Mastering Flashing: The Key to a Durable and Waterproof Roof

Welcome to the latest blog from Brehm Roofing, your premier roofing contractor in Gainesville, Florida, serving the entire North Central Florida region. Today, we delve deep into the world of roofing, focusing on a critical aspect that ensures the longevity and durability of your roof: Flashing. As a leading roofing company, we understand the importance of every component of your roof, and through this blog, we aim to educate you on why flashing is essential, especially in the unique climate of Florida.

What is Flashing, and Why is it Crucial for Your Roof?

Flashing is a material, usually made of metal, that is installed in various areas of your roof to prevent water from entering and causing damage. It is a thin layer of waterproof material that directs water away from critical areas of the roof, where the most water accumulation occurs. Typically, it is installed at the roof’s edges, joints, seams, and around roof openings. Its primary purpose is to create a water-resistant barrier that enhances the overall waterproofing of your roof, crucial for protecting your home from Florida’s heavy rainfalls and storms.

Florida Building Codes and Flashing

In Florida, roofing is taken seriously, especially considering the weather conditions the state is prone to. The Florida Building Codes specify that flashing shall be installed at wall and roof intersections, at gutters, wherever there is a change in roof slope or direction, and around roof openings. When the flashing is made of metal, it must be corrosion-resistant and comply with the thickness provided in RAS 111. These regulations ensure that every roof installation or roof replacement meets a standard of quality and durability, especially in areas prone to intense weather conditions. It is important that the roofing company doing your reroof replaces any damaged roofing flashing.

Types of Flashing and Their Specific Roles

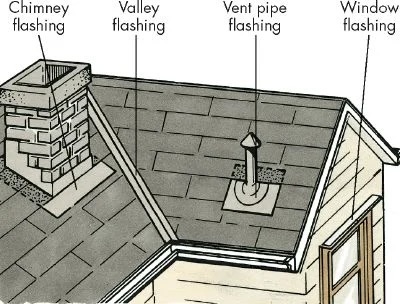

Let’s break down the different types of flashing typically used in roofing and their specific roles:

- Chimney Flashing: This involves layers of material installed around the base of the chimney where it meets the roof. It consists of apron flashing, step flashing, and sometimes counter-flashing to ensure no water seeps through the chimney and roof intersection.

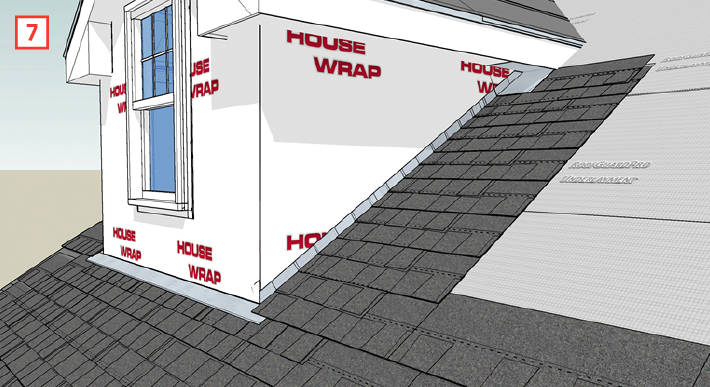

2. Side Wall Flashing: This type is used where the roof meets a vertical sidewall. It directs water away from the wall and into the gutter system, ensuring that no water penetrates the walls or roofing system.

3. End Wall Flashing: Similar to sidewall flashing, end wall flashing is used where the roof meets the end wall of a building, providing a water-tight seal between the roofing material and the wall

4. Dormer Flashing: Dormers are additional structures that protrude from the roof, and they require precise flashing around the intersections to prevent water from seeping in.

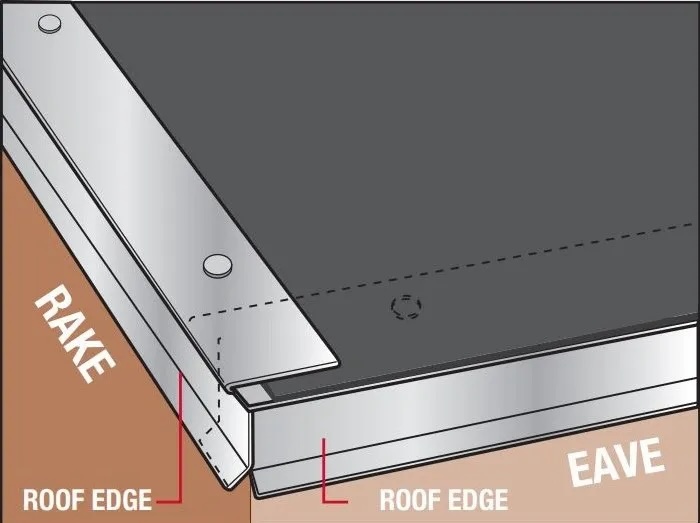

5. Drip Edge Flashing: Installed at the edge of the roof, drip edge flashing directs water away from the fascia and into the gutter, protecting the wooden board against water damage.

6. Skylights: Usually, skylights come with flashing kits specified by the manufacturer. These are designed to fit snugly around the skylight, ensuring that water doesn’t enter around the edges.

7. Pipe Flashing: Any pipes or vents protruding from the roof need flashing to seal the space between the pipe and the roof material, preventing leaks. The most common pipe flashing used at Brehm Roofing is the Bullet Pipe Boot. These boots are a one-piece flexible rubber TPE pipe flashing.

8. Valley Flashing: This is used in the internal angles of the roof, known as valleys. It can be made from aluminum coil roll or more commonly nowadays, a peel-and-stick membrane that offers superior protection against water.

Expert Insight on Flashing Techniques

In their comprehensive guide, “Roofing Flashing & Waterproofing,” the editors of Fine Home Building provide valuable insights into the application of flashing in roofing. They note, “Chimneys are flashed in much the same way as dormer walls. The difference lies mainly in what covers the upturned sides of the apron, or base, flashing and the step flashings. Whereas dormers have siding that comes down over the flashing, masonry chimneys use counter-flashing.” This detail highlights the subtle yet crucial differences in flashing techniques between various roof features, emphasizing the importance of expertise and precision in roofing work.

The Installation Process and Brehm Roofing’s Commitment

At Brehm Roofing, we specialize in all aspects of roof installation, including the precise installation of flashing. Our team of experienced professionals understands the intricacies of how different types of flashing work and the best practices for installation, especially considering the demands of Florida’s climate. We are well-versed in the Florida Building Codes and ensure that every reroof or new roof installation we undertake meets these stringent standards.

Whether you are considering a new roof installation or a roof replacement, understanding the importance of properly installed flashing can save you from future headaches. It’s not just about keeping your home dry; it’s about ensuring the longevity and durability of your roof. At Brehm Roofing, we pride ourselves on providing comprehensive roofing solutions that stand the test of time. For all your roofing needs, remember that quality, durability, and professional service are just a call away with Brehm Roofing.