Asphalt Shingle Roofing Fasteners

As a licensed roofing contractor, I understand the critical role that fasteners play in the stability and durability of a roof. Today, I’ll share a comprehensive guide on the different types of roofing fasteners, focusing specifically on those used in asphalt shingle roofing. From decking nails to shingle nails and cap nails, I’ll provide the insights you need to make informed decisions about the best fasteners for your roofing projects.

Introduction to Roofing Fasteners

Roofing fasteners are more than just nails; they are the backbone of roof durability and can significantly impact the lifespan of a roof. Selecting the right type of nail for each part of the roof is crucial in ensuring a secure, leak-proof, and weather-resistant finish.

Decking Nails: The Foundation of Roofing

The initial stage of roofing involves securing the roof deck, which can be made of plywood or OSB (Oriented Strand Board). For this task, the industry standard is to use decking nails that are 2 and 3/8 inches. These nails are designed to offer optimal penetration and hold, providing a strong base for the layers that follow. The length and diameter of these nails ensure they grip into the decking material securely, reducing the risk of uplift or movement caused by high winds or physical stress.

Shingle Nails: Varieties and Purposes

Moving to the outer layer, asphalt shingles are the most common roofing material due to their cost-effectiveness and reliability. The preferred fasteners here are 1 1/4″ nails, specifically crafted for this application. Let’s delve into the different types of 1 1/4″ nails available:

- Corrosion Resistant Nails: These nails are essential in areas with high humidity or coastal environments where salt spray is prevalent. Corrosion-resistant nails, including those made from stainless steel or coated with protective finishes, prevent rust and deterioration, thereby prolonging the life of the roof.

- Galvanized Nails: These are steel nails coated with a layer of zinc to offer enhanced resistance against corrosion. Galvanized nails are an economical choice for many environments, though they may not be sufficient in more severe climates.

- Stainless Steel Nails: Offering the highest level of rust resistance, stainless steel nails are ideal for regions subject to heavy rain or salt exposure. While they come at a higher cost, their longevity and durability make them a worthwhile investment for premium roofing projects.

- Copper Nails: Known for their durability and rust-proof properties, copper nails are not only functional but also add an aesthetic element with their distinctive appearance. They are particularly popular in historic or high-end residential applications.

Understanding which nails can rust is vital. Standard steel nails without any protective coating are prone to rusting, which can weaken the roof’s integrity. Always opt for appropriately treated nails according to the local climate and environmental conditions.

Cap Nails: Securing the Underlayment

For the underlayment, which provides an additional barrier against moisture and weather, cap nails are used to ensure a watertight seal. There are two main types:

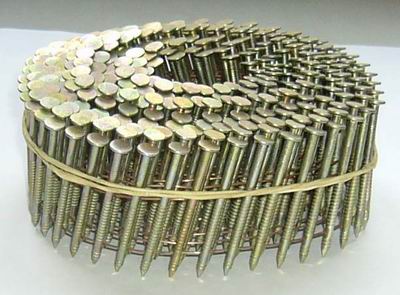

- Stinger Cap Nails: These nails are coiled and typically applied with a nail gun. They are efficient for large-scale projects, providing rapid application and secure fastening. The caps help distribute the load across a wider area, thereby reducing the risk of tearing the underlayment.

- Plastic Cap Nails: These are hand-driven and are best used in smaller areas or where precision is necessary. The plastic cap, much like with the stinger nails, helps protect the underlayment from tears and breaches, enhancing the overall water resistance of the roofing system.

Conclusion

Choosing the right type of roofing fasteners is not just a matter of preference but a crucial decision that affects the installation quality and longevity of a roof. Each type of nail serves a specific purpose and offers benefits in different scenarios. By understanding the properties and appropriate uses of each, professional roofers can ensure that their work stands the test of time and nature.

For those involved in roofing construction or maintenance, investing in the right fasteners is imperative. The above guide provides a clear framework for selecting the best nails for each part of the roofing process, contributing to a secure, durable, and high-quality roof that homeowners can rely on for years to come.